API/CPI/TPI Separator (Retrofit)

SERIES Retrofit Package

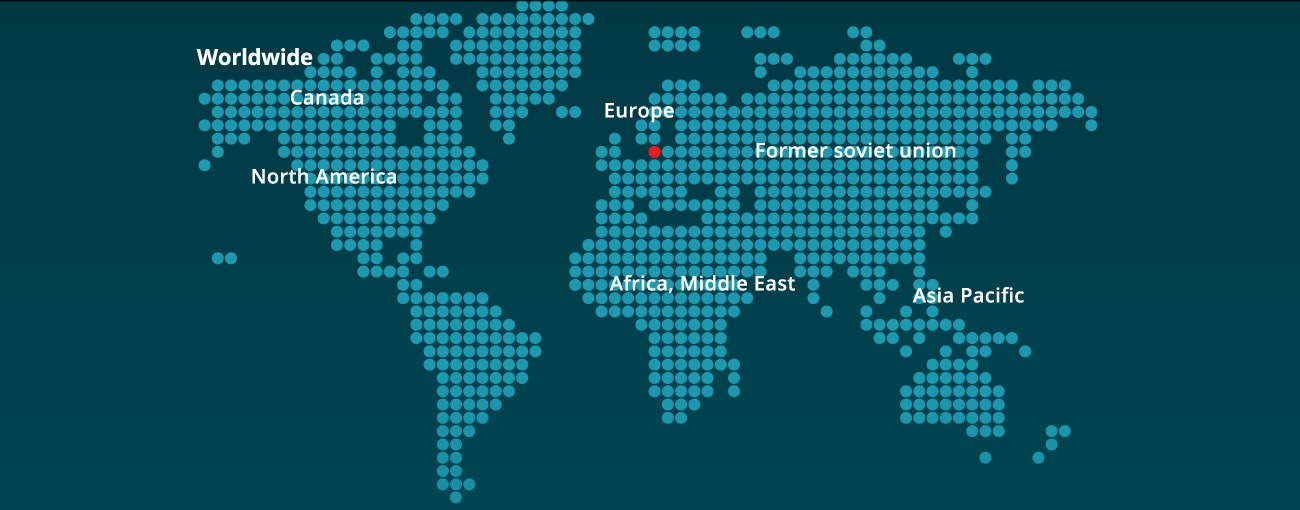

If your existing API/CPI/TPI, oily water separator is not functioning well, wether due to the design, poor effluent performance or fouling problems, we would be able to retrofit your existing API/CPI/TPI separator tank. These could be old large API pits at refineries or petrochemical plants or above the ground large steel tanks. We will add more plate surface per m3 of separator tank volume and per m2 of separator tank area then the execisting design, therefore we are able to increase efficiency. Important factors we take into consideration are; plate surface area, flow rate’s, sizing, efficiency and probably most important understanding the overall process and possible fouling issue’s. We could scheduele a plant visit, speak to the operators, undertand the system and see if it is worthwhile retrofitting. In close cooperation with the client and our engineering team we will create a customized retrofit design. Once the “Advanced” API/CPI/TPI Separator (retrofit) internals are delivered we can support during installation and start-up all around the world.

Menu

≡

╳

Menu

≡

╳

Download

Download