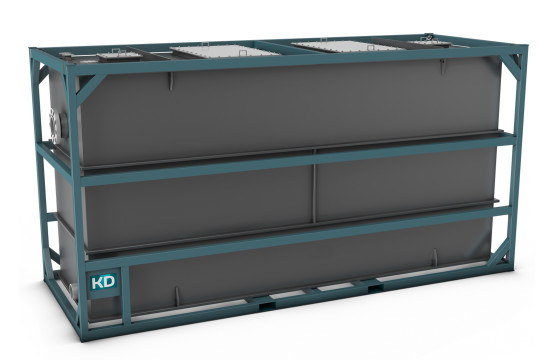

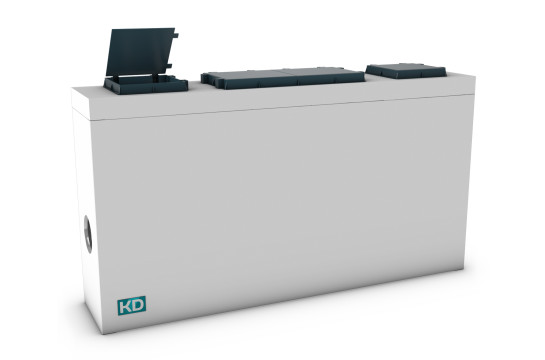

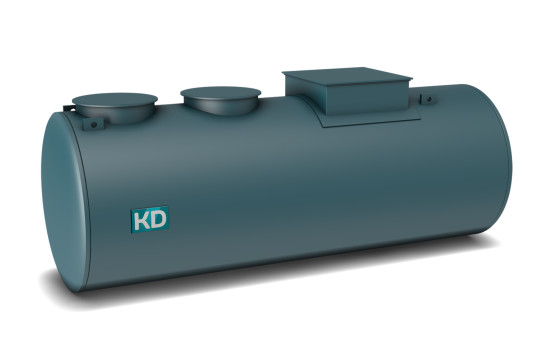

Stormwater Treatment Separator

SERIES SW390

Stormwater that does not soak into the ground becomes surface runoff, which either flows directly into surface waterways or is channeled into storm sewers, which eventually discharge to surface waters. Impervious surfaces (airports, industrial area’s, roads, parking lots and sidewalks) are constructed during land development. During rain storms and other precipitation events, these surfaces (built from materials such as asphalt and concrete), along with rooftops, carry polluted stormwater to storm drains. Water running off these impervious surfaces tends to pick up gasoline, motor oil, heavy metals, trash and other pollutants from roadways, parking lots and other surfaces.

Effective control of urban runoff involves reducing pollutant discharges. KD International Oily Water Run-off Separators are widely used to reduce the effects of urban runoff. The separator is designed to treat Free non emulsified oil and solids separation by use of our unique Coalescing Plate Technology.

Menu

≡

╳

Menu

≡

╳

Download

Download