Menu

≡

╳

Menu

≡

╳

- Home

- About us

- Rentals

-

All products

-

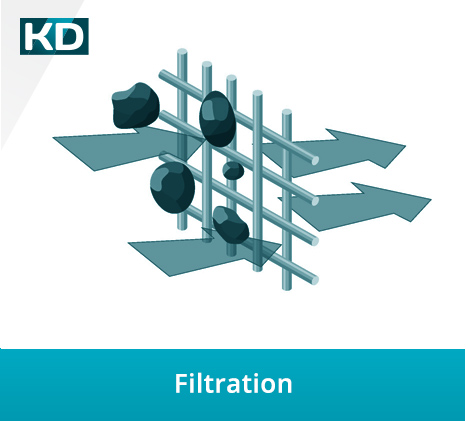

Filtration and Separation

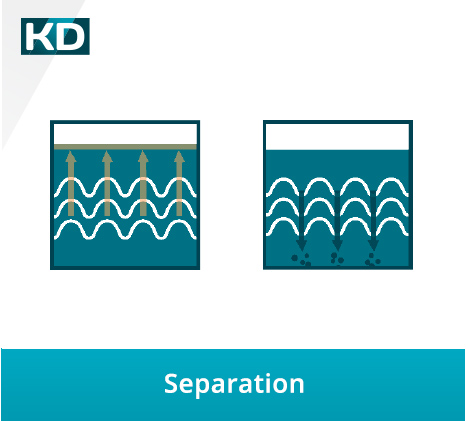

- Solids from Liquids

- Liquids from Liquids

- Filter Cartridges

-

Oily Water Separation

- Atmospheric Oily Water Separator

- Mobile Oily Water Separator

- Pressurized Oily Water Separator

- Emulsion Destabilization Skid

- Concrete Oily Water Separator

- Steel Oily Water Separator

- CPI/TPI Separator (above ground)

- CPI/TPI Separator (below ground)

- API/CPI/TPI Separator (Retrofit)

- Stormwater Treatment Separator

-

Filtration and Separation

-

Applications

-

Environmental

- Oil Spill Emergency Response

- Process Water Treatment

- Rainwater Run-off Treatment

- Rainwater Run-off Treatment, Airports

- Stormwater Treatment

- Temporary Oil Spill Removal

- Water Reverse Osmosis Desalination

- Amine Filtration

- Oil Water Clean Up

- Gas Condensate Mercury Removal

- Sour Water Coalescing Separation

- Waste Water Treatment

- Oily Waste Water Treatment

- Pre-Reverse Osmose Filtration

-

Upstream

- Completion Fluids Filtration

- Deck Drain Water Treatment

- Fracking Water Recovery

- Injection Water Filtration

- Offshore Seawater Reverse Osmosis

- Pipeline Flushing Filtration

- Produced Water Treatment

- Seawater Intake Filtration

- Glycol Separation Filtration

- Slop Water Treatment

- Well Testing Water Treatment

- Flowback and well clean-up treatment

- Water Flooding Filtration

- Well Bore Clean Up Filtration

-

Environmental

- Contact

Download

Download